Lamella sedimentation filter

In thickeners, the thickener surface increases in proportion to its capacity. Lamella sedimentation filter is used to save the area occupied by the thickener, or in cases where the solid concentration in the input load to the thickener is low and the area required to obtain the overflow water is much larger than the area required for the settled materials.

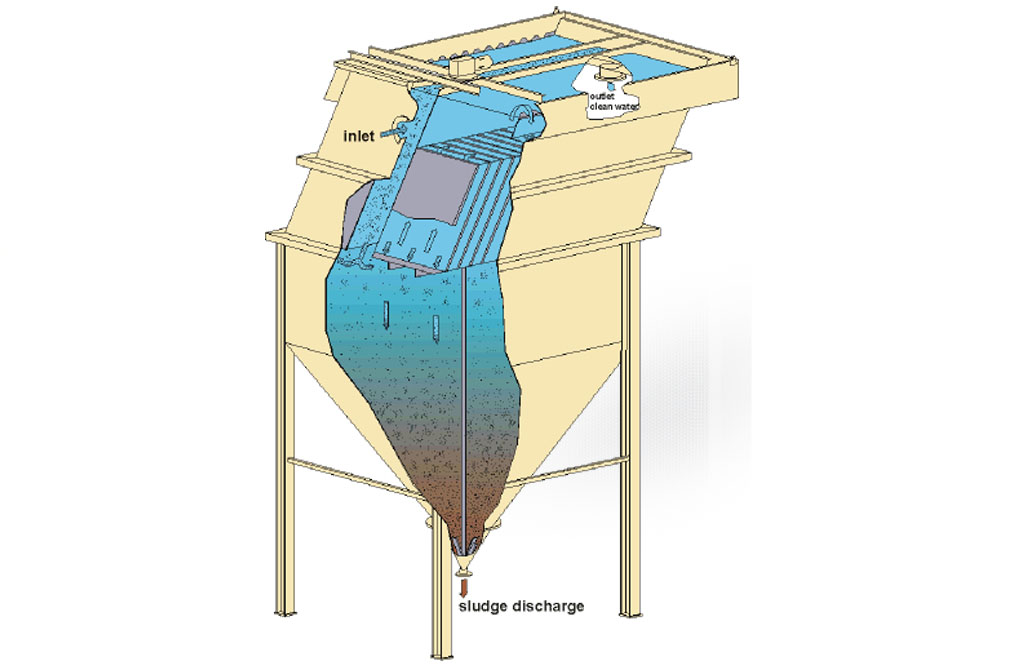

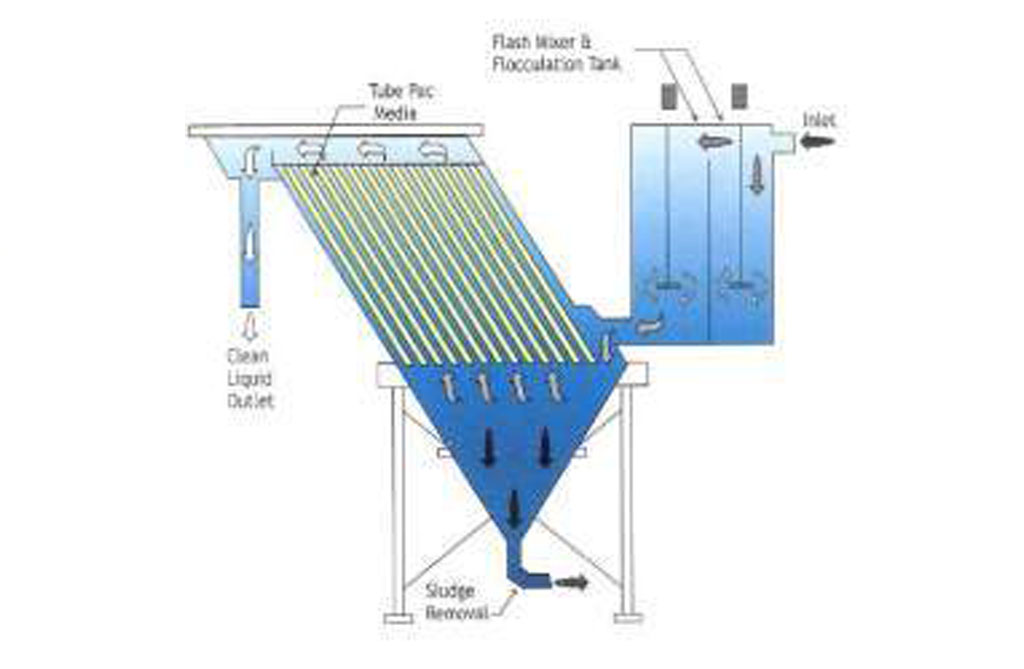

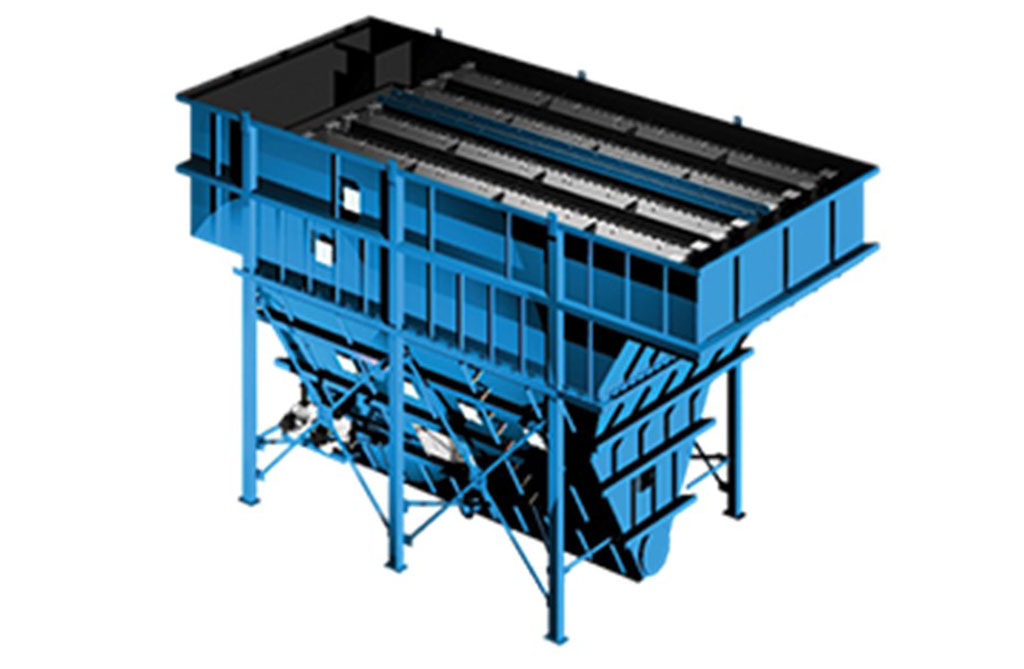

Inside this thickener, many inclined plates are placed parallel to each other and the input load is directed to the distance between these plates. In this way, the useful surface for sedimentation has increased. Lamella thickeners consist of two parts. Their upper part is in the form of a parallel plane, and the inclined plates are installed in groups with a slope of 45°- 55° inside it, and their lower part is in the form of a cone or cylinder.

The input load enters through the vertical chambers on the sides of the inclined plates and is transferred to the space between the plates through slot-like channel. On the top of each set of plates, there are end-to-end channels equipped with regulation holes for overflow. In this way, it apply a small hydraulic pressure on the inlet flow and causes the initial load to be uniformly distributed in the spaces between the plates and the amount of turbulence at the inlet points is minimized.

The solid particles in the inlet load settle on the inclined plates and move on them in the direction of the slope to be discharged into the lower tank. Considering that the input load enters the space between them from the side of the inclined plates, no upward movement is created in this part. After passing through the screens, the solid materials enter the laminar zone and therefore it is not possible to be mixed with the inlet load.

Briefly, lamella clarifier is obtained by turning a normal clarifier (thickener) up to an angle of 55°. By combining the principles of design, including reducing the distance for solid particles to fall and creating a slippery surface without friction, the settling speed and separation of solid particles increases. This type of thickener is used for pulp with particle size of 1-150 µm and concentration less than 15%.

The advantages of using a lamella decanter filter are as follows.

Need less area for installation and operation

Less water loss in surface evaporation phenomenon

The possibility of optimizing the ratio of clarifier and thickener surface

Reducing the retention time and material stoppage in the filter

Low heat loss and easy insulation of the filter

Easier transportation

Frequently asked questions about lamella sedimentation filter

The other advantages of using a lamella decanter filter are as follows

- Quick install

- Low investment costs