Filter Press

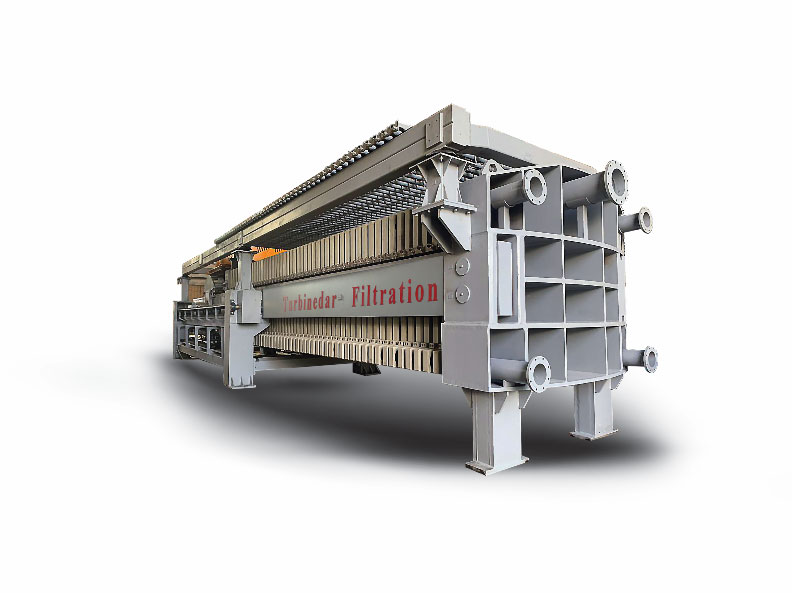

Turbinedar Company is a manufacturer of solid-liquid separation equipment, including filter press. The filter press machine is used to separate solid from liquid (in industrial slurries) and according to the type of its application in industries, solid particles (cake) resulting from filtration or filtered liquid (with solid particles less than 1% and in many cases, less than 100ppm) or both can be considered as a product.

Today, due to the need of water in mining industries and its shortage in mining sites, the filter press machine is used as a premium equipment in water recycling by recovering more than 90% of the water consumed in this industry.

The filter press is divided into three categories based on the type of pages used in it, as follows.:

Chamber (Recessed)

constant volume

Membrane

Variable volume

Turbinedar company uses different types of chambers (fixed volume) and membranes (variable volume) made of polymer in manufacturing of filter press machines.

Also, the filter press is divided into three models according to the way its plates are opened, which is a very effective factor in the duration of its process cycle, as follows:

1) Semi-automatic opening system: The hydraulic jack opening is done by the operator. (This system is for small filter presses)

2) Robotic opening system: In these machines, the plates are opened one by one or several plates together by a robot.

3) Automatic opening system trolley-type with four short jacks: in these machines, the plates are connected to each other with banana-shaped links, and the plates open quickly in one step. (This system is very useful in large filter presses to shorten the filtration cycle).

Turbinedar Company is recognized as the first manufacturer of heavy-duty filter presses and double feed filter presses in Iran, by updating and modernizing the filter press industry in accordance with global standards and modern technologies. Turbinedar company takes into consideration the DIN standard in the design and construction of this type of filters.

This company offers its products to customers with the appropriate performance and technical specifications after conducting laboratory tests and pilot plant in the research and development laboratory. Therefore, Turbinedar Company is known as a reliable reference for meeting the needs of all industries in the field of solid filtration from liquid, such as chemical, mineral, oil and gas, petrochemical, food and pharmaceutical, power plant, water and wastewater industries , and other industries.

General specifications of filter presses produced by Turbindar company

work pressure

Working pressure 6 to 16 bar

Filtration level

Filtration surface 10 to 1000 square meters

The humidity of the output cake

The humidity of the output cake is 10 to 20%.

The dimensions of the pages

The dimensions of the plates are 1500, 2000 and 2500 mm

Suitable for

Heavy Duty

Dewatering from

Dewatering from tailings and concentrates of copper, iron, aluminum, gold, etc

Turbinedar Company is the only Iranian company that manufactures and owns the technical know-how and the patent of the one-stage quick opening system that reduces the cake discharge time in the filter press.

Advantages of filter press

- Simple and easy dewatering operation for different materials.

- Having a high filtration area by occupying a small area of the environment

- Ability to create variable capacity by increasing or decreasing the number of plates

The filtration operation cycle in a fully automatic filter press machine

All steps of a filtration operation cycle in a filter press machine include 11 steps in order of feasibility are as follows:

Applications:

Mining industries

Solid-liquid separation in mineral processing, Tailings dewatering (processing of copper, iron ore, lead, zinc, gold, aluminum, molybdenum, processing of non-metallic minerals such as coal, kaolin, ceramic manufacturing industries and ...)

Oil, gas and petrochemical industries

water and waste water treatment, oil waste treatment in accordance with the standard for discharge into the environment, separation of water, mud and organic matter (separation of oil, mud, water and oil)

Food industry

to separate solid materials from liquid in the sugar industry and glucose producing industries, oil extraction industries to separate oil from oil seeds, yeast separation in food and juicing industries.

Chemical industries

potash, salt, sodium phosphate production industries

Industrial water and wastewater treatment

dewatering from all kinds of sludge produced from physical, chemical or biological wastewater treatment, recycling and optimization of the water and wastewater treatment process.

Types of filter press

Turbinedar company uses different types of chambers (fixed volume) and membranes (variable volume) made of polymer in the manufacture of filter press devices.

Also, the filter press is divided into three models according to the way its plates are opened, which is a very effective factor in the duration of its process cycle, as follows :

Fast opening automatic robotic filter press

In these devices, the plates are opened one by one or several plates together by a robot.

Advantages of the robotic automatic fast opening system:

- High opening speed

- Reducing the time of each operating cycle

- Increasing the number of cycles per hour and increasing capacity

- Creating diversity in capacity

- Time management of washing fabrics

Characteristics of filter presses with fast automatic robotic opening system

| Row | Device Model | working pressure (bar) | Cake thickness (mm) | number of pages | Filtration surface (m2) | Cake capacity (m3/cycle) |

|---|---|---|---|---|---|---|

| 1 | TRFP63 | 12-6 | 40-25 | 50-10 | 35-5 | 0.6-0.1 |

| 2 | TRFP80 | 12-6 | 40-25 | 50-10 | 45-9 | 1-0.1 |

| 3 | TRFP100 | 12-6 | 50-25 | 85-15 | 130-20 | 3 -0.3 |

| 4 | TRFP120 | 12-6 | 50-25 | 85-20 | 195-44 | 5-0.5 |

| 5 | TRFP150 | 12-6 | 50-25 | 100-30 | 345-100 | 8-1 |

| 6 | TRFP200 | 12-6 | 50-25 | 100-30 | 665-195 | 16-2.5 |

Automatic opening system trolley-type with four short jacks

in these devices, the plates are connected to each other with banana-shaped links, and the plates open quickly in one step. (This system is very useful in large filter presses to shorten the filtration cycle).

Advantages of one-step quick opening system

- Reducing cake discharge time from about 20 minutes to less than 5 minutes per cycle

- Increasing the number of filtration cycles per hour (3-5 cycles per hour)

- Increasing the efficiency of the device by at least 30%

- Reducing production costs

Specifications of filter presses with one-step fast opening system (Trolly type)

| Row | Device model | working pressure (bar) | Cake thickness (mm) | Number of pages | Filtration surface (m2) | Cake capacity (m3/cycle) |

|---|---|---|---|---|---|---|

| 1 | TTFP150 | 16-6 | 50-25 | 100-50 | 345-170 | 9-2 |

| 2 | TTFP200 | 16-6 | 50-25 | 100-50 | 665-325 | 16-4 |

| 3 | TTFP250 | 16-6 | 50-25 | 100-50 | 1000-490 | 20-5 |

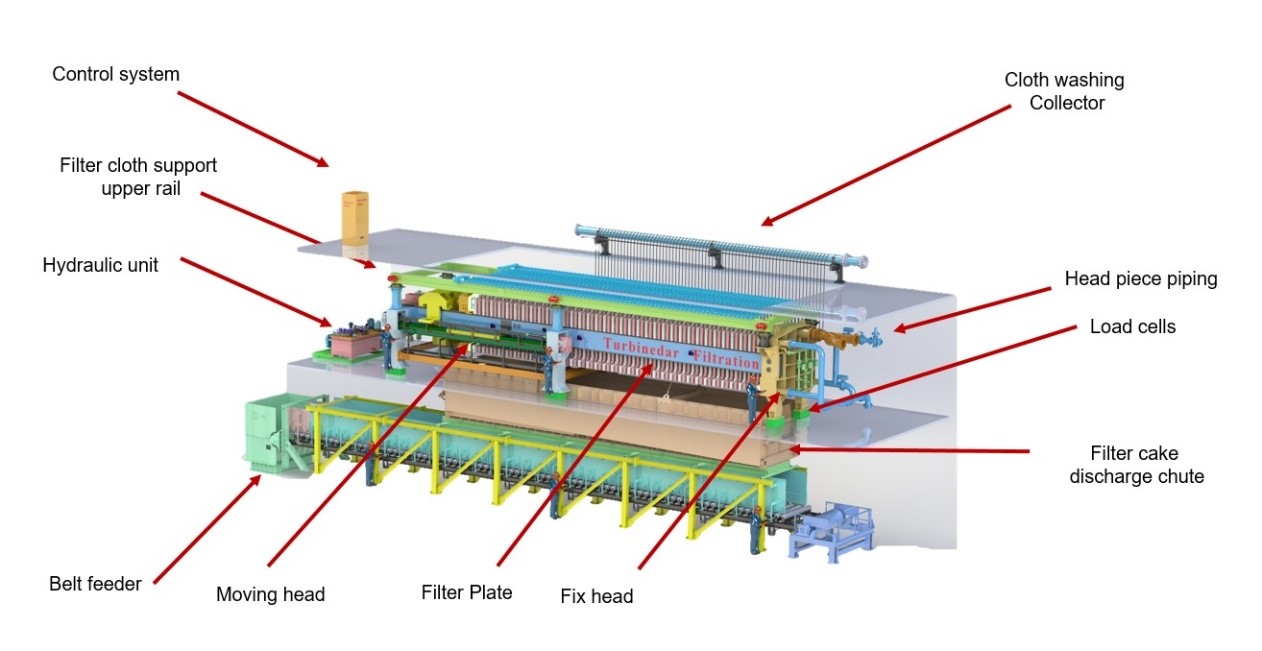

Press filter components

All components of the filter press are shown in the figure below :

In general, a filter press machine has different equipment and parts, which are divided into two main and optional equipment parts. The main equipment of the filter press is required to set up and work with the filter press, and the optional equipment of the filter press is the equipment that is necessary to facilitate the operation of the filter press.

The main and optional equipment in making a filter press machine is as described in the table below;

| Row | The main equipment for setting up and working | Additional and optional equipment |

|---|---|---|

| 1 | The main body of the device (including fixed plate, movable plate, main beams | System of opening and closing pages (fast opening system, fully robotic or robotic link) |

| 2 | Membrane or Chamber plates | Control and weighing system (loadcell) |

| 3 | Filter cloth | Screen and fabric vibration system to fully discharge the cake |

| 4 | Hydraulic system | Automatic fabric washing system |

| 5 | Pneumatic system | Drip tray |

| 6 | Piping system (slurry, liquid exit, air entry and exit, entry and exit of grout path washing water) | Piping system at the head of the machine (one square meter on both sides of the filter press machine) |

| 7 | Electrical panel system, automation and device control | Filter press process valves |

| 8 | Shot (to empty the cake) | |

| 9 | feeding pump | |

| 10 | Belt feeder | |

| 11 | air compressor |

In addition to the main equipment of the filter press, Turbinedar Company makes optional equipment that can be manufactured in its own company and obtains the items that can be supplied from reliable companies

Press filter plates

Plates are one of the main components of the filter press machine. The material, type and quality of the plates directly affects the performance of the machine. The plates used in filter presses are divided into two types of membrane plates and chamber plates, a brief description of these types of plates is provided below.

1- Membrane plates of variable volume

Turbinedar company uses membrane plates made by reputable European companies for filter press devices. The forming plates in this machine are flexible and diaphragmatic and have the ability to squeeze the cake. After the end of the filtration operation and cake formation, the air blowing operation is performed on these plates, which causes the swelling of the membrane of the plates and puts pressure on the cake and the continuation of the dewatering operation.

The use of membrane plates is an advantage for this type of filter and it shortens the cake dewatering time, reduces the filtration time and also makes the cake drier by using higher pressure in the pressing step in the filter press machine.

2- Chamber plates (Recessed)

Turbinedar company uses PP chamber plates to manufacture filter press devices with fixed volume. These plates are completely hard and rigid and the cake is formed in the space between these plates. The dryness of the resulting cake in this sample of filter press machines is different depending on the feeding pressure and the characteristics of the input slurry.

Filter press plates are able to produce cakes with different thicknesses. Determining the type of plate according to the thickness of the cake, the type of solid in the slurry and the strength of the filter cake is determined by following instructions of test and evaluation in the process laboratory or pilot plant in the research and development laboratory of this company.

Filter cloth

In the quality of the filtration performance, the cloth covering the filter plates plays a fundamental role. The quality and select of cloths directly affect the moisture content of the cake and the quality of the filtered liquid, therefore, choosing the right cloth with the right graining (mesh) is very important.

In the quality of the filtration performance, the cloth covering the filter press plates plays a fundamental role. The quality and select of cloths directly affect the moisture content of the cake and the quality of the filtered liquid, therefore, choosing the right cloth with the right graining (mesh) is very important.

Main body of filter press machine

The main body and structure of the filter press machine includes a moving plate, a fixed plate and the main beams (on which the filter press plates are placed on both sides). The design of this structure is based on DIN ISO 12100 design standards and stress analysis in the structure is done based on the standard and with ANSYS software. All the parts of this part are metal and are welded according to the ASME and AWS D1.1 standard recipes. After constructing the main beams, taking into account the high operating pressure, it is necessary to make sure that they are level and can bear enough load (no possible deformation).

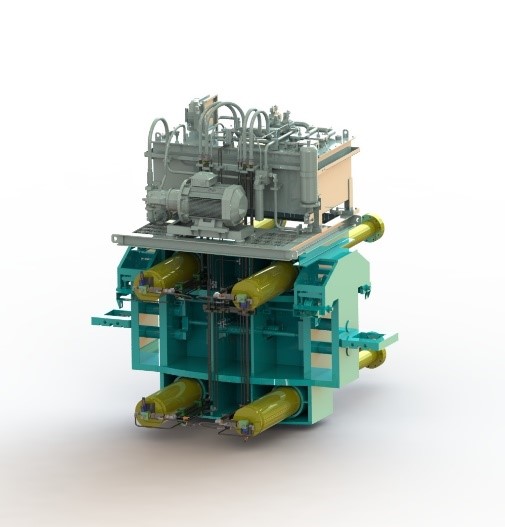

Hydraulic system

The hydraulic system of the filter press machine is used to open and close the plates and also to seal the filter press plates. The hydraulic system includes; Jack, oil pump, oil tank, control valve, hose and related instruments. The hydraulic jack is the main part of the hydraulic system.

In order to ensure the performance of the jack on the filter press devices, to withstand the operating conditions and real loads, Turbinedar Company uses ISO, DIN, AISI and ASME standards in designing, calculating, determining the technical specifications of the hydraulic jack and also choosing the right materials in the construction of the hydraulic system.

According to the dimensions of the filter press, the number of its plates, the importance of sealing the plates, etc., the hydraulic system can be designed, manufactured and installed as a single jack, double jack and four jack.

Pneumatic system

The pneumatic system is responsible for dividing and transferring the compressed air of the compressor to the valves, instruments and all pneumatic equipment. The compressed air produced by the compressor enters this system and opens and closes the pneumatic equipment according to the programming and commands sent from the control panel.

Piping system

This part includes piping for the inlet of the slurry, piping for the filtrate outlet, piping for the inlet and outlet of air, and piping for the inlet and outlet of the washing water of the slurry path.

Control system

The control system controls and programs various parts of the filter press including electrical, mechanical and hydraulic system parts. In the filter presses manufactured by Turbinedar Company, the PLC system is the core of the control systems.

The control system includes the control panel, where the HMI screen is responsible for controlling the entire process.

System of opening and closing plates

Turbinedar company has the technical knowledge and design of the fast-opening system of the filter press according to the most advanced methods available. This company, according to the needs of users of filter press in various industries and their application, produces the following opening systems.

- Fully automatic trolley (Fast opening)

- One by one robotics

- Robotics with banana-shaped links

Washing system

The washing system washes the clothes after each working-cycle or according to the detection of the load cell of the weight of remaining dust and cake on the clothes after several cycles of filtration. This system is installed on the machine in one of three ways, according to the type of material on which filtration is done, manual, robot or simultaneous washing system.

Drip tray

This equipment in the filter press collects leaking water between the plates during the washing of the feeding pipelines and also the washing of the clothes and prevents the mixing of these waters with the cake formed in the filter press.

Additional equipment of the filtration line

Air compressor and air storage tank

Lorem Ipsum Lorem Ipsum Lorem Ipsum Lorem Ipsum

Cake conveyor belt (Belt Feeder)

The cake discharged from under the filter press is dropped onto a conveyor belt called a belt feeder and transported to the cake storage area.

In fact, the belt feeder is placed under the shot, whose dimensions are proportional to the opened length of filter press plates and shot.

This device consists of several parts as follows.

1) Belt feeder structure

2) gearbox and drive

3) conveyor belt

4) Rollers

Homogenizer tank

Lorem Ipsum Lorem Ipsum Lorem Ipsum Lorem Ipsum

Fabric washing pump

Lorem Ipsum Lorem Ipsum Lorem Ipsum Lorem Ipsum

Feeding pump

Lorem Ipsum Lorem Ipsum Lorem Ipsum Lorem Ipsum