Candle Filter

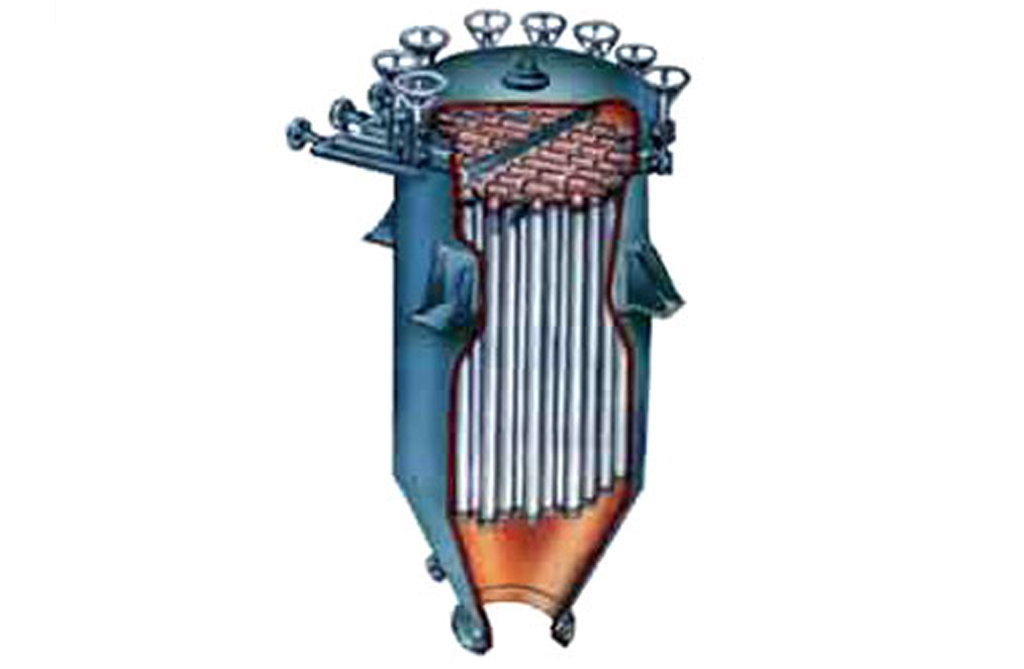

A candle filter is a type of filter for separating solid from liquid. In this type of filter, a number of candle filters are placed vertically in a pressurized tank.

The most important part of this filter is the cylindrical mesh nets (candle-like) by which separation is done. During the filtration time, which takes place in a high-pressure tank, liquid is forced into the filter from the outside. Solid particles are formed on the surface of the filter and a uniform cake is created. The cake remains on the surface of the filter agent due to the concave-convex profile and the constant pressure difference.

The filtered liquid is transferred through the ducts in the candle filter to the upper part of the pressurized tank. After forming the cake, air flow is usually used to achieve a cake with higher dryness. At the time of discharge, counter-current air or a vibrator is used to discharge the cake from the ducts installed for it.

One of the special advantages of this type of filter is that this filter can work both with and without the help of a filter (pre coat). The homogeneous quality of the product, uniform capacity, high purity of the filtered liquid, and minimum operating costs have made this type of filter used in different industries.

The filtration area in this type of filters is between 4 and 250 square meters, the operating pressure is up to 10 bar, the operating temperature is up to 250 °C, and the particle size that can be separated is up to 0.5 microns.