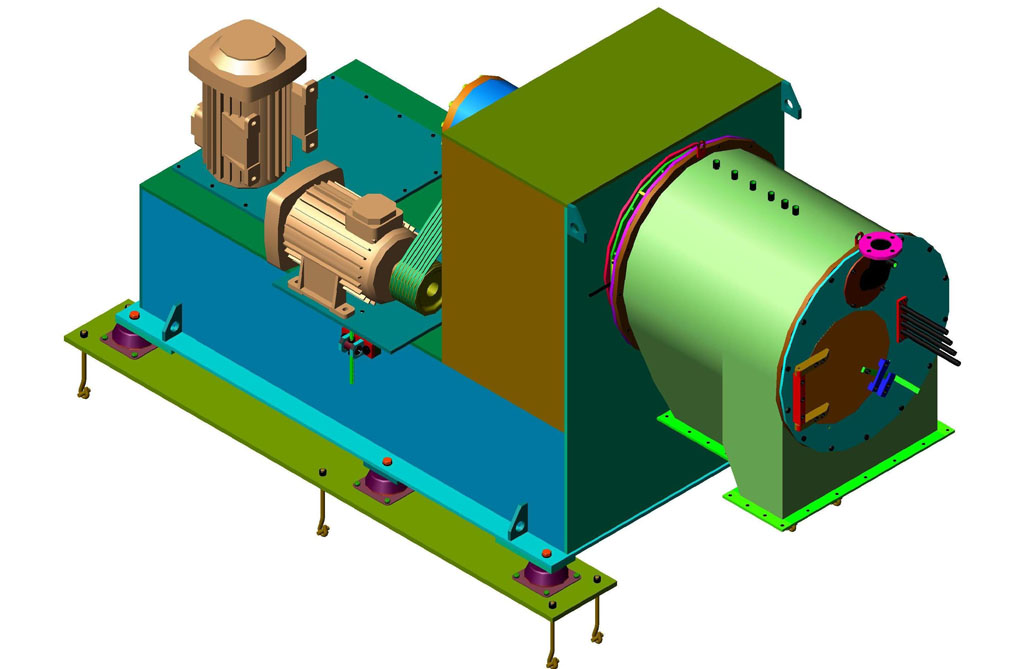

Pusher centrifugal

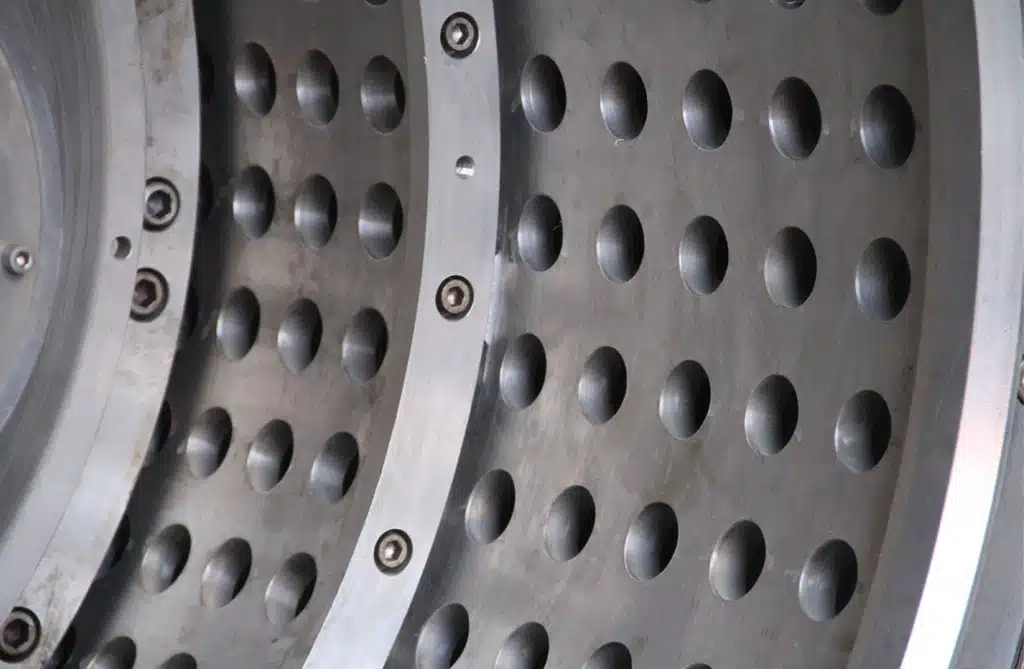

This type of centrifuge is used for dewatering, drying and separating materials (fibers and powders) continuously. In this machine, the input mixture enters the centrifuge through the feed tube and is distributed uniformly inside the centrifuge basket when it meets the distributor. The solid phase formed on the basket can be washed by water jets. Dewatering is done by centrifugal force created in the centrifuge. At the same time, the solid phase is moved to the front of the centrifuge by the reciprocating force of the basket and the dried solid phase is discharged

The advantages of using a pusher centrifuge are:

Drying and separating the dry material from the wet material without breaking and damaging the input fiber and crystals

Continuous and non-stop separation process

The possibility of washing the outer surface of crystal and fiber

Very little occupied space

Low maintenance cost and low energy consumption

Ability to control the humidity of the output cake

Uses in separation and filtration

- Food industries (edible salt, salt washing, food powders, etc.)

- Industries (medicinal salt, soap making, medicinal powders, glycerin...)

- Chemical industries (fertilizer, plastic, PVC, cellulose, ...)

- Petrochemical and chemical,

- pharmaceutical industries