Decanter Centrifuge

The decanter centrifuge with continuous operation, operating pressure up to 8 bar and operating temperature -20 to 15 °C, is used for separating solid from liquid or liquid from liquid, thickening and clarifying slurry in various chemical and petrochemical industries. The use of decanter centrifuges in all industries except mining industries is the first choice due to the simplicity of use, quick installation, and continuous operation.

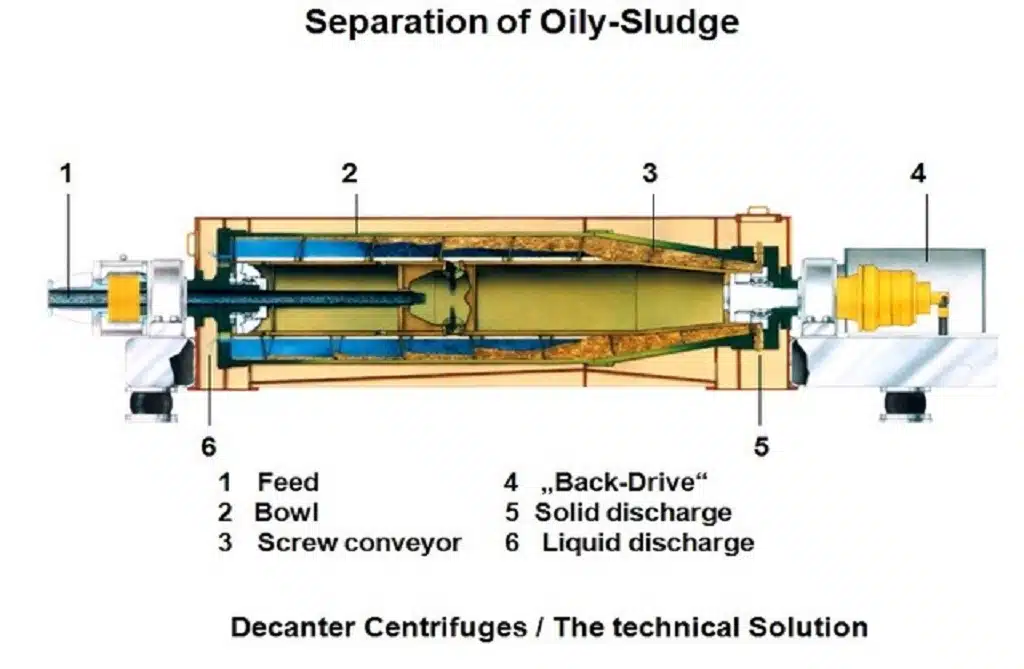

The operation of the decanter centrifuge device is such that, when the slurry enters the device (1), solid particles are thrown towards the wall using centrifugal force (2). In the external bowl (4), the solid particles are transferred to the other side of the centrifuge using the screw (3) and are discharged from the path (5). The clarified liquid also exits from the other side of the decanter centrifuge from the path (6).

Turbinedar company has the ability to manufacture decanter centrifuges for two-phase separation in different capacities from 2 to 40 cubic meters per hour.

This company has used technologies in the design of the centrifuge and the placement of the motor and the shell so that the machine has minimal vibration. The main parts in contact with the material are usually made of corrosion-resistant materials (stainless steel or Duplex). There is a possibility of polymer or ceramic coating for screw edges. Hydraulic or solar gearbox can be used to make this device. It is also possible to set this device for different speeds.