In the research and development laboratory of Turbinedar Company, the necessary tests are performed according to the amount, type and size of solid particles in the slurry, temperature and operating pressure in order to choose the best filtration method with the highest efficiency and also to determine the characteristics of the filtered liquid and filter cake

The characteristics determined in these tests are as follows :

1- Determining the type of device (separation filter) suitable for separating solid from liquid

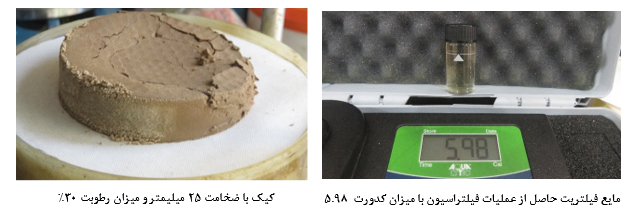

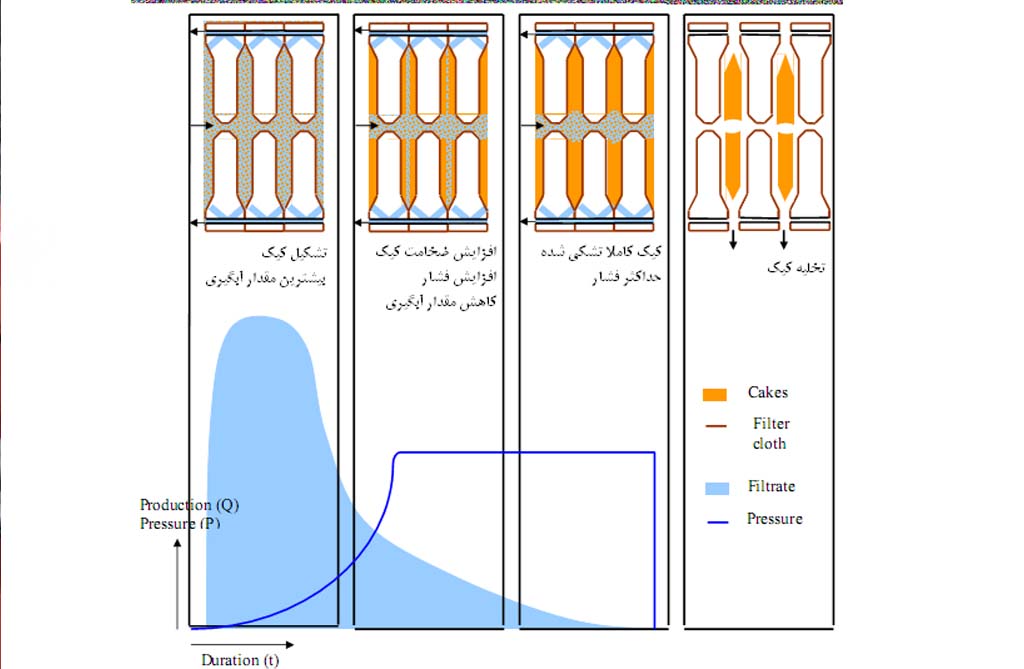

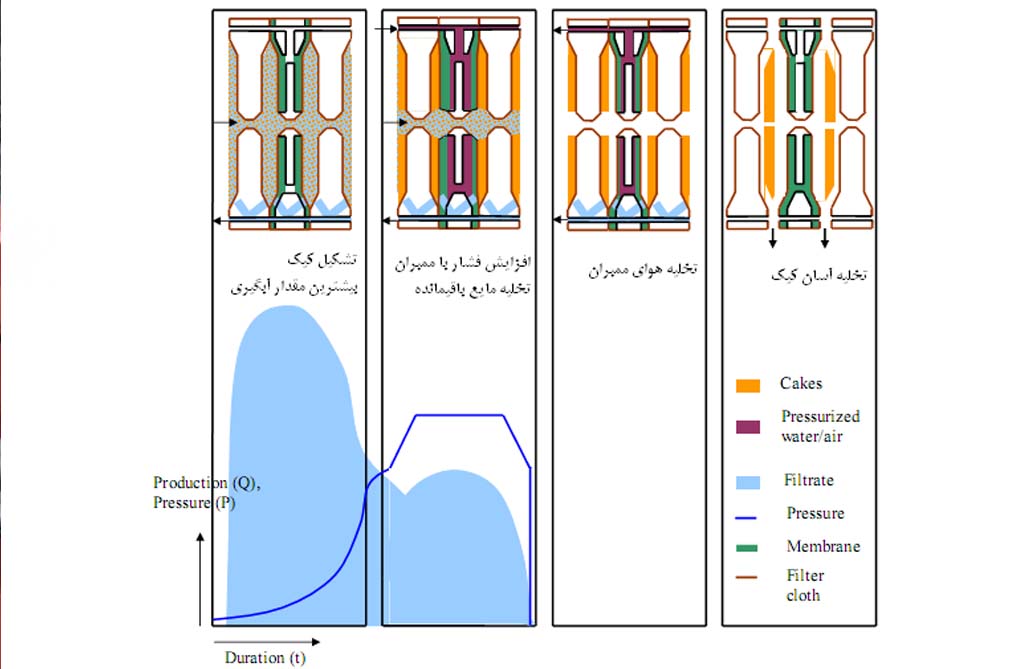

2- Determining and optimizing the operating conditions of filtration

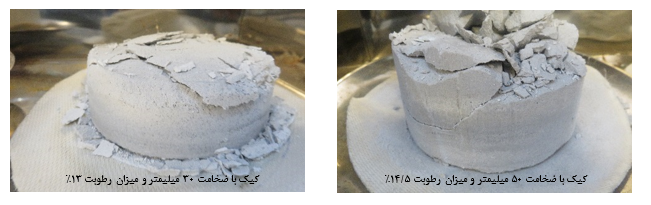

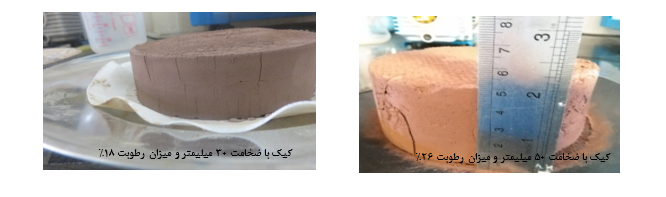

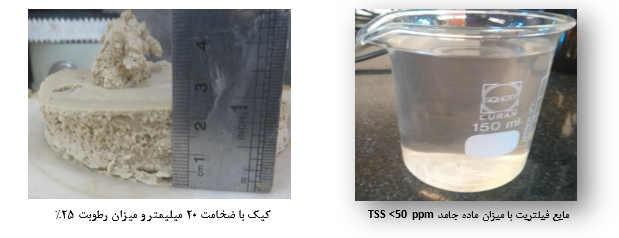

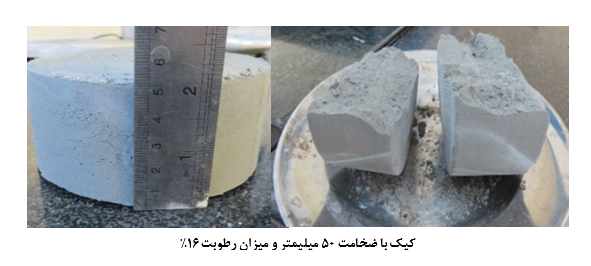

3- Determining the properties of slurry, filtered liquid and also formed filter cake

4- Determining the optimal size and capacity of the suitable device for separation (filtration)

5- Determining the right type of fabric, fabric mesh and fabric type for filtration systems that perform separation with filter fabric.

6- Determining the amount of air required for blowing air into the cake (to dry the cake) and blowing air into the feeding channel.

Turbinedar Company has the full expertise and ability to conduct laboratory and pilot plant tests, as well as analyze and developing laboratory data obtained by experts and use this data in the design of equipment on an industrial scale. This company always conducts these tests before starting any project as a prerequisite for designing and implementing the project

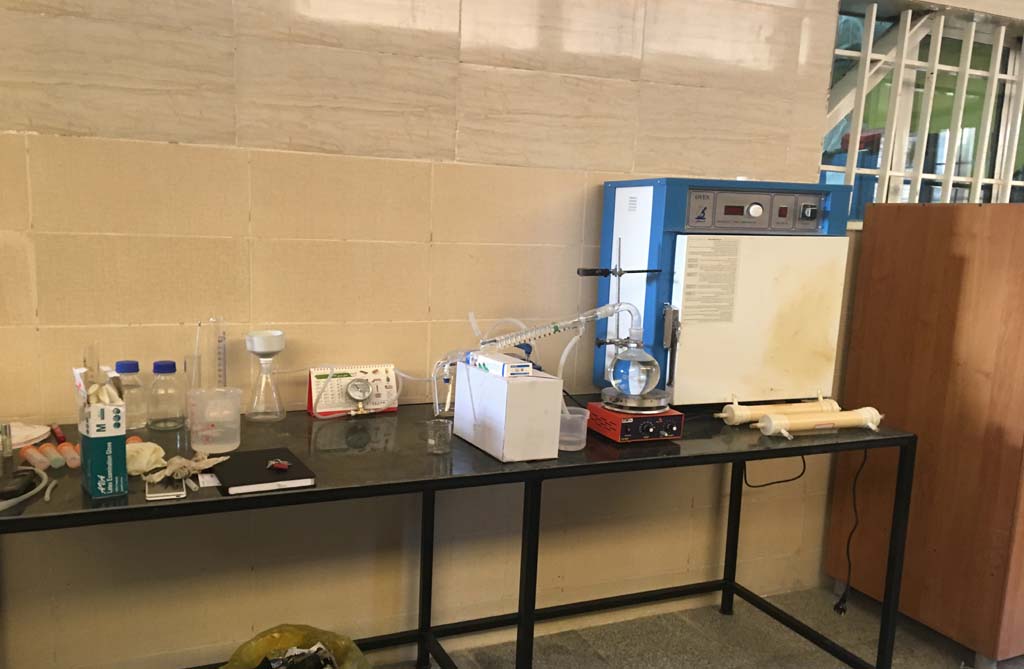

The facilities available in the research and development laboratory of Turbinedar Company are as follows:

- Laboratory scale pressure filtration test system

- Pressure filtration test system on a pilot plant scale

- The system for making polymer flat filters (laboratory)

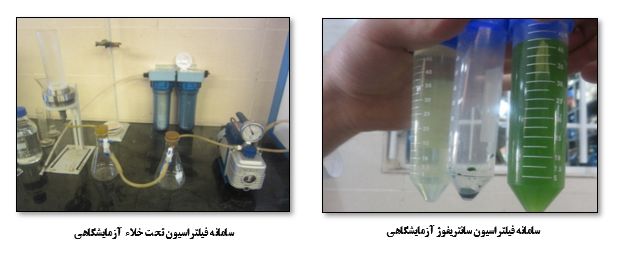

- Laboratory scale vacuum and centrifugal system

- Vacuum and centrifugal system on a pilot plant scale

- Laboratory system of micro-ultrafiltration membrane filtration