Diffusion

Extraction is a widely used separation method in the mineral and food industries, and it is liquid extraction from liquid or liquid extraction from solid. In this method, the desired substance is extracted from liquid or solid substances by using a suitable solvent.

One of the most important stages of sugar extraction in the sugar and sugarcane industry is the stage of producing raw syrup with the maximum amount of sugar and pulp with the minimum percentage of sugar. The process of extracting sugar from beets is called syrup extraction or diffusion extraction.

In the diffusion device, according to the process of osmosis and membrane percolation, which is a function of the difference in sugar concentration inside and outside the beet cells, sugar substances penetrate from the sugar beet or sugar cane tissue to the surface and it is solved inside the water that the opposite is entered into the machine.

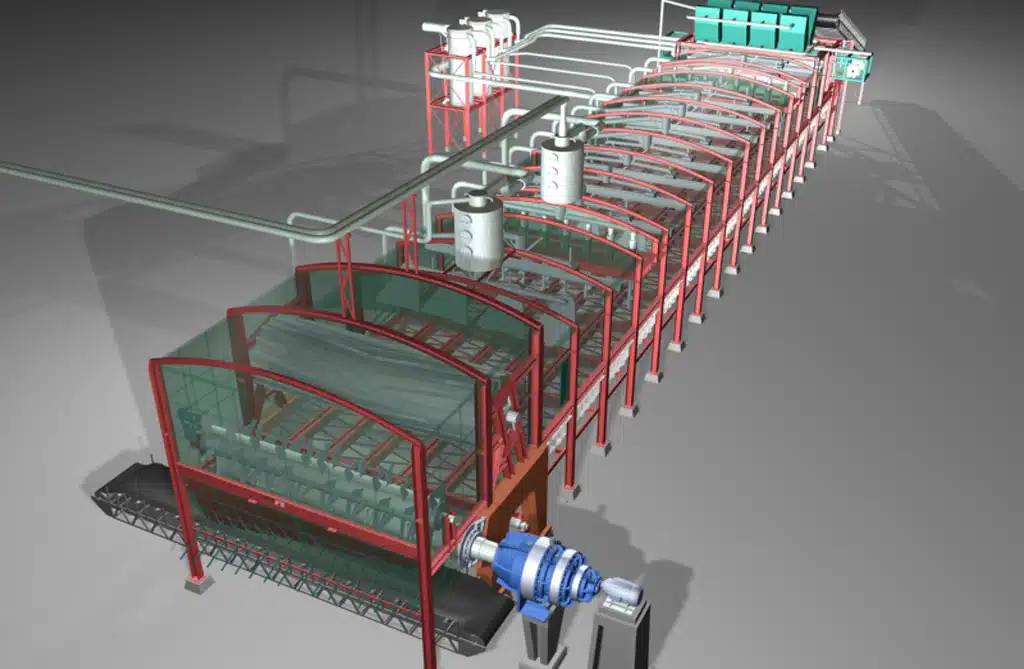

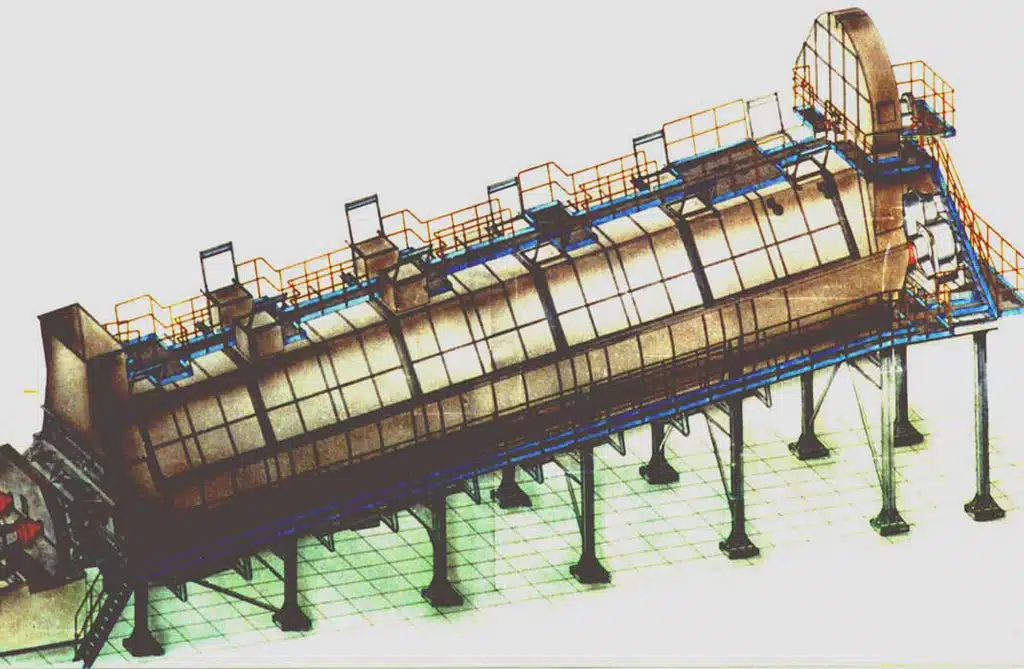

In many industries, including oil extraction from oil seeds, extraction from sugarcane and sugar beet, extraction equipment is designed and manufactured in different ways. For different applications, the extraction and diffusion systems include components such as baskets, screws, paddles, and gearboxes to help transfer and distribute materials.

Turbinedar Company is a manufacturer of diffusion devices with capacity of 4,000 to 15,000 tons per day (based on beet), a height of up to 22 meters, a mixer diameter 4 to 8 meters and length of 7 to 10 meters.